Thin film materials are playing an increasingly significant role in various industrial and scientific fields. These materials, characterized by their extreme thinness, exhibit unique physical, chemical, and electrical properties that make them ideal for a wide range of applications.

Preparation Methods

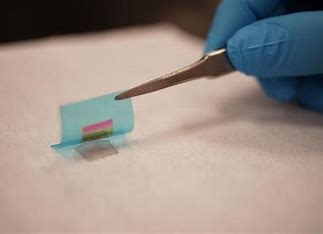

The preparation of thin films involves several key methods, including physical vapor deposition (PVD), chemical vapor deposition (CVD), electrochemical deposition, sol-gel process, and molecular beam epitaxy (MBE). PVD techniques such as thermal evaporation, sputtering, and pulsed laser deposition (PLD) are widely used due to their versatility in depositing films of almost any material. CVD, on the other hand, is particularly suitable for growing high-purity and high-performance solid materials.

Structural Forms and Properties

Thin films can exist in single-crystal, polycrystalline, or amorphous forms. Single-crystal films have a structure similar to bulk materials, with a well-defined crystal orientation. Polycrystalline films consist of small crystals with different orientations, while amorphous films lack structural regularity. These different structural forms contribute to the diverse properties and applications of thin films.

One notable property of thin films is their modified electrical characteristics compared to bulk materials. This can be attributed to changes in valley energy and conduction band energy located between polycrystalline grains. Additionally, thin films often exhibit excellent light absorption properties, making them suitable for applications in solar cells and other optoelectronic devices. Their high selectivity and sensitivity to certain elements and compounds also make them excellent candidates for gas sensors.

Applications

The applications of thin film materials are vast and diverse. In the electronics industry, thin films are crucial for the manufacture of integrated circuits, where they play a dominant role in all general processes. Superconducting thin films, for instance, offer faster speeds, lower losses, and greater capacity compared to semiconductor-based digital circuits. Conductive thin films, such as ITO films, are widely used in liquid crystal displays (LCDs) and solar cells due to their combination of conductivity and transparency.

Ferroelectric thin films, known for their ferroelectricity, piezoelectricity, pyroelectricity, and nonlinear optical properties, find applications in microelectronics, optoelectronics, integrated optics, and micro-electro-mechanical systems (MEMS). Resistance thin films, or thin film resistors, are highly precise and stable, making them ideal for replacing lower-precision thick film resistors.

Future Prospects

The field of thin film materials science is continuously evolving, with ongoing research aiming to improve film quality, reduce energy consumption, and explore new applications. With advancements in deposition techniques and characterization methods, the potential for innovative thin film-based technologies is immense. From enhancing the performance of electronic devices to developing new sensors and energy-harvesting systems, thin film materials are poised to make significant contributions to the future of technology.