Thin films, also known as “thin film” in English, are an integral part of modern technology, playing a crucial role across various industries and scientific fields. Defined as an extremely thin layer of material, typically measured in nanometers (nm) in the semiconductor industry, thin films exhibit unique properties that make them indispensable in numerous applications.

One of the key applications of thin films is in superconducting materials. Superconducting thin films, deposited using processes like evaporation and sputtering to achieve a thickness of less than 1 micrometer (μm), offer unparalleled advantages in digital circuitry. Compared to semiconductor-based circuits, superconducting circuits operate faster, with lower loss and higher capacity. This makes superconducting thin films a highly desirable material for microwave communication devices such as antennas, resonators, filters, and delay lines, offering exceptional sensitivity that surpasses traditional materials like gold and silver.

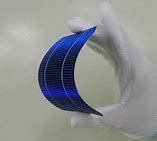

Conductive thin films are another significant category, encompassing both semi-conducting and conducting films. Transparent conductive thin films, for instance, are capable of conducting electricity while maintaining high transparency in the visible light spectrum. These films are widely used in liquid crystal displays, solar cells, and various optical applications. Materials like indium tin oxide (ITO) are particularly popular in this context, although research and development in this area are ongoing to improve preparation methods and expand applications.

Ferroelectric thin films are another functional material with immense potential. They exhibit ferroelectricity, piezoelectricity, pyroelectricity, and nonlinear optical properties, making them suitable for applications in microelectronics, optoelectronics, integrated optics, and micro-electromechanical systems (MEMS). Storage devices, sensors, transducers, and optoelectronic devices are just a few examples of how ferroelectric thin films can be utilized.

Semiconductor thin films, available in amorphous and polycrystalline forms, also play a vital role. Amorphous semiconductors, lacking a crystalline structure, have a similar energy band structure to crystalline semiconductors, including conduction, valence, and forbidden bands. However, the presence of numerous defects in amorphous semiconductors introduces localized energy levels within the forbidden band, significantly impacting their electrical and optical properties.

In addition to these, thin films also find applications in resistance films, known as thin film resistors, which offer high resistance accuracy and low temperature coefficients. These resistors are typically manufactured by depositing a material with a certain resistivity onto an insulating surface using techniques like vacuum evaporation or sputtering.

Thin film technology, encompassing the preparation, testing, and related technologies of thin films, is crucial for enhancing the performance and lifespan of various devices. The ability to precisely control the composition, structure, and thickness of thin films at the nanometer scale enables the creation of materials with tailored properties for specific applications.

In conclusion, thin films are indispensable in modern technology, with a wide range of applications across various fields. From superconducting materials to conductive and ferroelectric thin films, the unique properties of these materials make them essential for advancing technology and improving our daily lives. As research and development continue, we can expect to see even more innovative applications of thin films in the future.