Thin films, as a complex yet fascinating concept, play a pivotal role in modern technology. These thin layers of material, ranging from single atoms to a few millimeters in thickness, exhibit unique properties that make them indispensable in various industries and scientific fields.

Definition and Characteristics

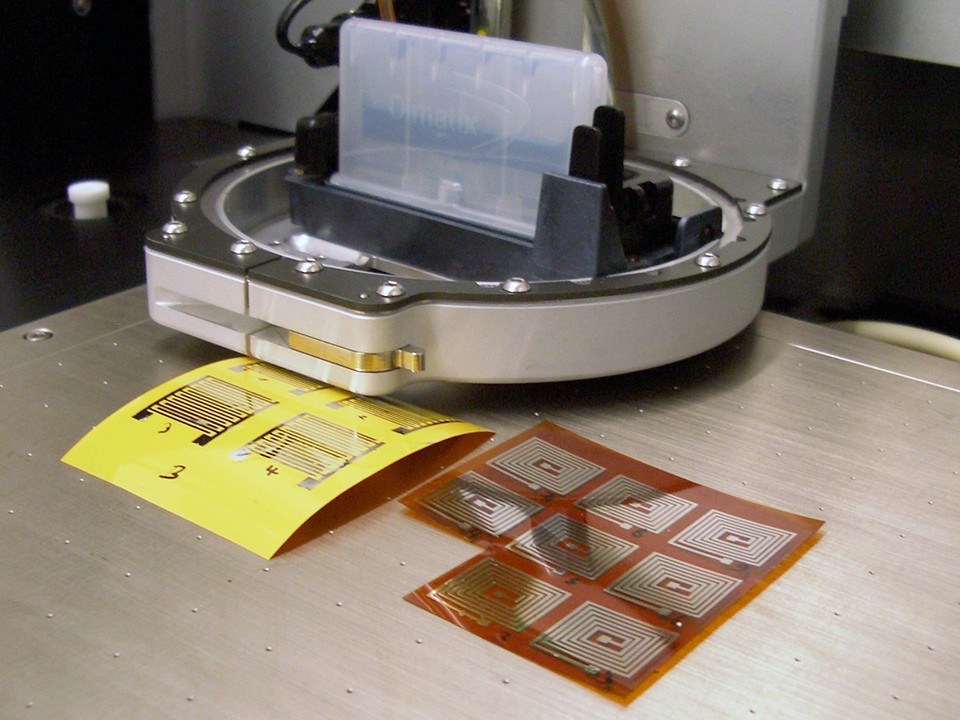

A thin film can be defined as a thin layer of material deposited on a substrate. It is characterized by its small thickness and the specific properties it inherits from its composition and structure. These properties, including physical, chemical, and electrical characteristics, are crucial for various applications.

Types of Thin Films

- Superconducting Thin Films: These films, with a thickness less than 1 micrometer, are deposited using processes like evaporation and sputtering. They offer unparalleled advantages in digital circuits, providing faster speeds, lower losses, and higher capacities compared to semiconductor materials. Superconducting thin films are also essential in microwave communication devices, such as antennas, resonators, and filters, due to their high sensitivity.

- Conductive Thin Films: Conductive thin films are materials that can fulfill specific electronic functions. They are classified into semi-conducting and conducting films. Transparent conductive films, in particular, are both conductive and highly transparent in the visible light range, making them ideal for applications in liquid crystal displays, solar cells, and various optical fields.

- Ferroelectric Thin Films: Ferroelectric thin films possess ferroelectricity and are typically tens of nanometers to a few micrometers thick. They exhibit excellent ferroelectric, piezoelectric, pyroelectric, electrical, and nonlinear optical properties. These films are widely used in microelectronics, optoelectronics, integrated optics, and micro-electro-mechanical systems (MEMS).

- Resistive Thin Films: Also known as thin film resistors, these films offer high resistance accuracy and low temperature coefficients. They are commonly used in ceramic substrates and are manufactured through processes like vacuum evaporation and sputtering.

Applications of Thin Films

The applications of thin films are vast and varied. In the field of electronics, they are crucial for the fabrication of solid-state devices, ball bearings, cutting tools, and components for rocket engines and nuclear reactors. In addition, thin films are essential in the production of high-quality epitaxial films, polysilicon, and various insulating and passivating films.

Preparation Techniques

Several methods are employed to prepare thin films, including physical vapor deposition (PVD), chemical vapor deposition (CVD), electrochemical deposition, sol-gel processing, and molecular beam epitaxy (MBE). Each method has its own set of advantages and is chosen based on the specific requirements of the application.

In conclusion, thin films represent a cornerstone of modern technology. Their unique properties and diverse applications make them indispensable in various industries. As research continues to advance, we can expect to see even more innovative and groundbreaking applications of thin films in the future.