In the realm of modern technology, thin films play a pivotal role, especially in the field of integrated circuit manufacturing. This article introduces several types of thin films, exploring their unique applications and characteristics.

Superconducting Thin Films

Superconducting thin films, with a thickness less than 1 micrometer, are deposited through processes such as evaporation and sputtering. These films exhibit exceptional properties, including zero resistance, making them ideal for creating microwave communication devices like antennas, resonators, filters, and delay lines. These devices possess high sensitivity unmatched by conventional materials like gold and silver. Superconducting thin films are crucial in the development of superconducting transistors and high-speed electronics due to their energy-saving and ultra-fast response capabilities. The advancement of high-temperature superconductivity is a key area of international competition, with potential applications in electricity, communications, national defense, and healthcare.

Conductive Thin Films

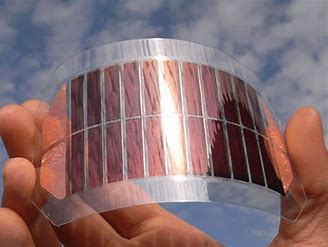

Conductive thin films serve specific electronic functions and are categorized into semi-conductive and conductive films. Semi-conductive films primarily include epitaxially grown silicon single-crystal films, CVD-grown doped polysilicon films, and semi-insulating polysilicon films. Insulating films, such as silicon oxide and silicon nitride, are also significant. Metal films, including aluminum, gold, and nickel-chromium, are widely used. Transparent conductive films, which combine conductivity with high transparency in the visible light range, encompass metal, oxide, other compound, polymer, and composite film systems. ITO (Indium Tin Oxide) films are particularly noteworthy, finding applications in liquid crystal displays, solar cells, and various optical fields.

Ferroelectric Thin Films

Ferroelectric thin films, ranging in thickness from tens of nanometers to a few micrometers, exhibit ferroelectricity. These films possess excellent ferroelectric, piezoelectric, pyroelectric, electrical, and nonlinear optical properties. They are crucial in microelectronics, optoelectronics, integrated optics, and micro-electromechanical systems (MEMS). Preparation methods include SOL-GEL, MOCVD, PLD, and sputtering. Ferroelectric thin films are primarily used in memory devices, sensors, transducers, and optoelectronic devices.

Thin Film Resistors

Thin film resistors, also known as film resistors, are chip resistors with high resistance accuracy and low temperature coefficients. They are typically made of ceramic substrates with resistance materials deposited through vacuum evaporation, sputtering, or chemical deposition. These resistors offer resistance accuracy up to ±0.05%, temperature coefficients of ±5ppm/°C, and stability of ±0.02%, making them ideal replacements for low-precision thick-film chip resistors.