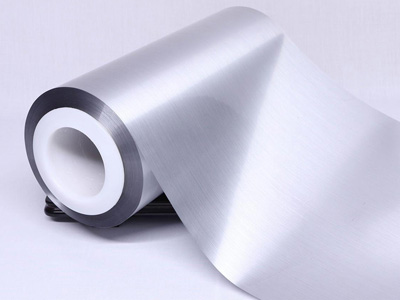

Vacuum aluminum-plated film has unique metallic luster, good barrier properties and environmental protection characteristics

Vacuum aluminum-plating technology is a physical vapor deposition method. Its core is to evaporate and deposit molten metal aluminum onto a pre-treated film substrate under a high vacuum environment. This process ensures the uniformity and adhesion of the aluminum layer, making the final product not only beautiful in appearance but also excellent in performance.

Core features:

| Brilliant luster | Through vacuum aluminum-plating technology, an ultra-thin aluminum layer is evenly deposited on the surface of the film, giving the product a dazzling metallic luster and enhancing the beauty and attractiveness of the packaging. |

| Excellent barrier | The aluminum-plated layer effectively blocks oxygen, moisture and ultraviolet rays, prolongs the shelf life of the items in the package, and protects food, medicine, etc. from the external environment. |

| Environmental protection and energy saving | Compared with traditional aluminum foil materials, vacuum aluminum-plated film is lighter and thinner, reduces resource consumption, and can be recycled and reused, which is in line with the trend of green packaging. |

| Flexible application | Suitable for various packaging forms, such as flexible packaging, composite bags, labels, cover films, etc., and is widely used in food, medicine, daily chemicals, tobacco and other industries. |